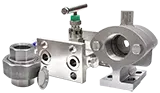

An industry leader in thermowells and instrumentation hardware with a global client base.

Mac-Weld is one of North America’s largest thermowell and instrumentation hardware manufacturers. We work with a variety of materials from basic Carbon Steel to Stainless Steel and exotic materials such as Titanium, Chrome Molys, Hastelloy and Monel.

With a global client base of over 500 companies, we provide blanket requests, as well as specialty welding and machining requests, to meet the ever-changing needs of our customers. On average we produce over 150,000 Thermowells every year for a variety of industries.

On-time

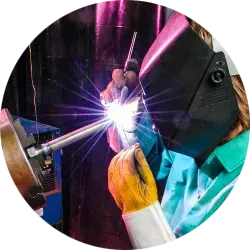

Our expertise in welding from basic Carbon Steel, Stainless Steel and exotic materials such as Titanium, Chrome Molys, Hastelloy, Monel and many more welding techniques covered under the boiler pressure code, is one of the key reasons our client base stays constant. It also extends to machining techniques including deep hole drilling. We provide quality assurance from inline inspection thru to final inspection that may include PMI, Dye penetrant, Hydro-Static testing and X-ray, NACE MR 0175, material test reports and more.

Precision

At Mac-Weld, quality and precision are woven into everything we do. We stay on top of certifications through timely audits and reviews as per our ISO Standard ISO 9001:2015 QMS. We have CRN numbers for specific needs, we provide Orifice Plates inspection by Coordinate Measuring Machine (CMM) Verification, and have robotic welding capability to meet UT Phase Array Testing to a 100%, in-house. We also offer 100% traceability, NACE MR 0175, and MTR upon request.

Global

Top-tier support is standard when it comes to working with us. We are constantly collaborating with our clients and working with them closely to ensure their goals are met. We provide a depth of experience and expertise in a number of industries that’s highly valued by our clients. Not only do we provide standard and custom products to our clients, we also provide our products under private label to some of our global customers in instrumentation and OEM.

TSSA Certified

We are now certified for fabrication, assembly and repair of Welded & Non-Welded category A,B,C,D,E,F and H type fittings in accordance with CSA Standard B51 Boiler, Pressure Vessel and Pressure Piping Code, ASME B31.1 Power Piping and ASME B31.3 Process Piping.

ISO Certified QMS

As an ISO certified QMS business, our products are manufacturing using the highest quality control systems. This gives our customers the satisfaction and consistency required for such specific pieces. The ISO 9001 framework results in less waste, reduced costs and higher quality.